Precision isn’t just a priority in military-grade manufacturing but is essential for achieving excellence. We specialise in CNC machining for defence, providing solutions that meet the stringent demands of military applications.

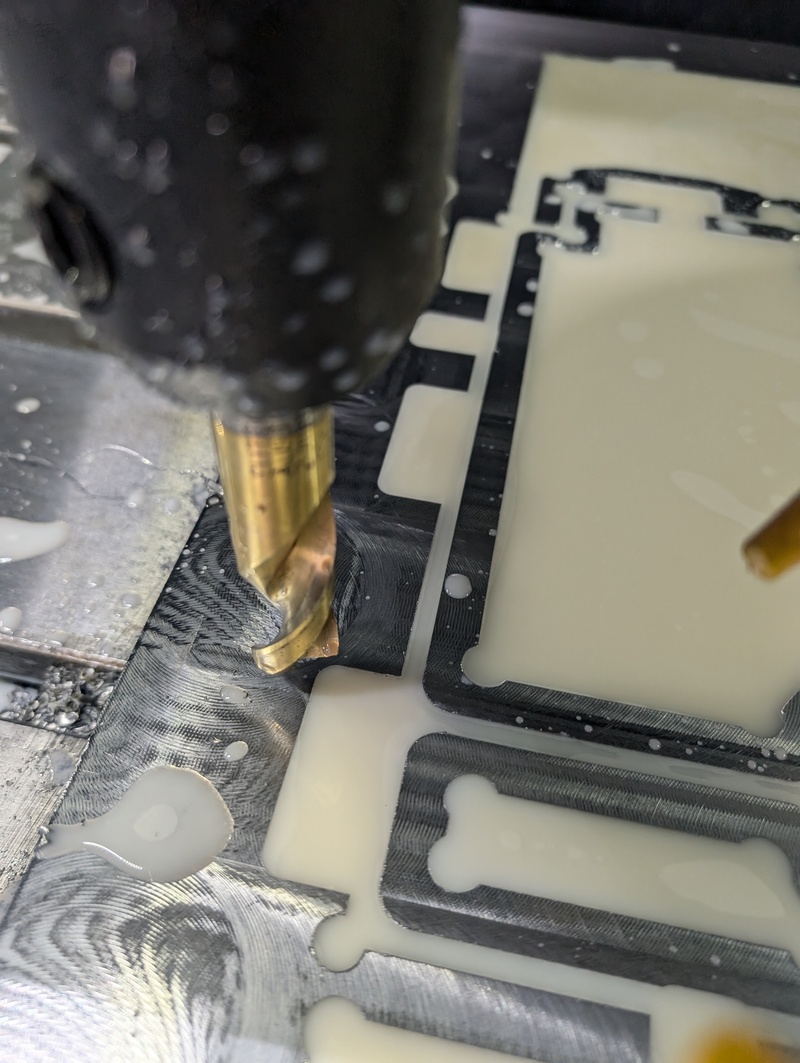

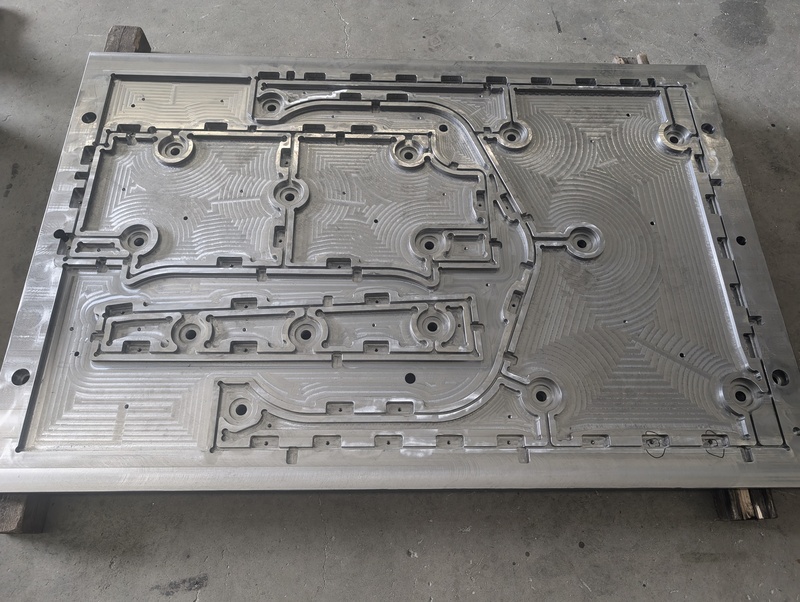

Our CNC machining services ensure accuracy and reliability, from intricate weapon components to advanced aerospace parts. This cutting-edge technology goes beyond basic machining processes – our CNC systems can create complex, three-dimensional designs in a single run, streamlining production and reducing waste. The result is faster output and consistent quality for the defence sector, even with highly intricate components. With military precision and innovative solutions, MK CNC Engineering supports the critical needs of defence manufacturing.Leveraging state-of-the-art CNC technology, we deliver unmatched precision in manufacturing complex components for defence applications. Our processes are designed to achieve exact tolerances and repeatable quality, vital for mission-critical parts.

In military manufacturing, there’s absolutely no margin for error. Our advanced CNC systems offer superior capabilities that include:

With years of experience in precision machining for military projects, MK CNC Engineering has established a trusted reputation for delivering solutions that meet strict quality and performance standards.

Our team specialises in bespoke CNC manufacturing, from steel machining for robust defence systems to custom prototyping, ensuring that every component is tailored to address the unique challenges of military applications.

We are committed to consistent, high-quality production. Every component is manufactured to meet the most demanding military standards, ensuring reliability in mission-critical situations.

By embracing cutting-edge technology and automation, we offer manufacturing solutions that not only meet today’s demands but are also scalable for the evolving needs of modern defence operations.

We prioritise the highest quality standards, ensuring every part we manufacture meets the strict demands of the defence sector, helping to ensure mission success.

We cater to diverse defence manufacturing needs, including:

Our CNC machining services produce precision parts, from triggers to barrels, guaranteeing the durability and accuracy required for reliable weapon performance.

Designed to withstand extreme conditions, our aerospace solutions ensure flawless production of aircraft and helicopter components, maintaining the highest levels of safety and performance.

We manufacture specialised components for military vehicles, including interior panels, cylinder heads, and transmissions, all engineered for custom defence applications.

Our expertise in prototyping accelerates innovation. We efficiently create and refine prototypes for weapons, tools, and machinery, enabling faster production cycles and continuous design enhancements.

At MK CNC Engineering, we are dedicated to supporting your defence manufacturing needs with precision, innovation, and reliability. Our team of experts is committed to delivering tailored CNC machining solutions that uphold the highest quality and performance standards in every project.

Ready to strengthen your defence capabilities? Contact us today to discuss your project requirements and discover how our cutting-edge technology can help your business grow.

In modern defence manufacturing, CNC machining for defence is no longer optional—it’s indispensable. The ability to deliver high-quality, reliable components directly impacts military readiness and operational success.

We offer CNC machining solutions designed to meet the unique needs of the defence sector. Contact us today to discuss how our advanced capabilities can enhance your defence system manufacturing projects while ensuring compliance with the industry’s rigorous standards. Let us help you optimise your manufacturing processes with cutting-edge technology and expertise.

Our CNC machining services consider various metallic, plastic, and composite materials to address a full range of materials involved, depending on the specific client project.

Lead times differ based on the complexity and dimension of the project. Our speed is prioritised since we will stay in touch with you to set a timeline geared toward making it all work for you.

Yes! From small prototype runs to massive runs, we can handle any size project consistently and efficiently.

Certainly! Our professional engineering team is available to partner with you to develop an exact version of the custom CNC machining services that fit the needs of your program.

What separates us from the rest all boils down to quality, innovation, and customer satisfaction. Advanced manufacturing technology plus a team of skilled professionals allow us to provide custom solutions that perfectly meet your specific needs.